Supply Chain Forecasting: How to Win with Data and AI

Supply chains are under pressure.

Unpredictable demand. Shipping delays. Market shocks. These disruptions are more than operational setbacks. They are costly.

A recent report found that disruptions cost companies an average of 6 to 10 percent of annual revenue, not to mention the reputational damage caused by failing to deliver.

To stay competitive, businesses need more than reactive planning. They need accurate forecasting, typically implemented within a data analytics platform, to predict what is coming and make better decisions.

This article breaks down how forecasting works, why it matters, and how leading companies are improving supply chain forecasting to reduce costs, enhance service, and increase adaptability in uncertain markets.

What Is Supply Chain Forecasting and Why Is It Important?

Supply chain forecasting is the process of using data to predict future supply and demand. It helps businesses plan for what products they will need, when they will need them, and in what quantity.

At its core, forecasting is about making smarter decisions. It helps companies anticipate customer demand, reduce waste, and avoid shortages or overstock.

Forecasting plays a central role in supply chain management. It connects different parts of the supply chain, from sourcing to production to delivery.

When done well, forecasting helps businesses:

- Reduce risk by anticipating disruptions and preparing for them.

- Improve inventory levels by ordering just what is needed.

- Deliver better service by meeting customer demand on time.

- Control costs by avoiding excess stock or rushed shipments.

- Streamline operations by aligning teams across planning, logistics, and sales

Without accurate forecasting, companies often rely on guesswork. That can lead to missed sales, lost customers, and higher operating costs.

Forecasting does not guarantee perfect results, but it does give companies a much stronger foundation for making decisions, adapting faster, and competing more effectively.

Discover GoodData analytics for supply chain

Take supplier and inventory management to the next level with advanced BI and analytics software.

Learn more

Demand forecasting vs Supply Forecasting: Key Differences

There are two main types of supply chain forecasting:

- Demand forecasting estimates future customer demand.

- Supply forecasting predicts future availability of materials or products.

The two are related but serve different purposes. Demand forecasting helps companies prepare for what customers want, while supply forecasting helps them ensure they can deliver it.

Here is a quick comparison:

| Feature | Demand Forecasting | Supply Forecasting |

|---|---|---|

| Focus | Predicts customer demand | Predicts availability of supply or inputs |

| Key Data Used | Sales history, market trends, promotions | Supplier performance, inventory levels, lead times |

| Main Goal | Align production and inventory with demand | Ensure materials and products are available |

| Used By | Sales, marketing, planning teams | Procurement, logistics, and operations teams |

| Helps With | Avoiding stockouts or overproduction | Preventing delays and managing inventory risk |

| Common Challenges | Sudden demand shifts, market volatility | Supply chain disruptions, supplier delays |

Purpose and Benefits of Forecasting in Supply Chain Management

The main purpose of forecasting in supply chain management is to align supply with demand. When companies can anticipate what is coming, they can plan more efficiently and avoid surprises.

Here are the key goals of forecasting in supply chain operations:

- Avoid overstock and stockouts by correctly planning inventory: Accurate supply chain demand forecasting is essential here.

- Support production and logistics: Schedule manufacturing, staffing, and shipping around expected needs.

- Enable long-term planning: Guide decisions on supplier contracts, warehouse space, and capacity.

- Increase resilience: Prepare for risks like supply chain disruptions, seasonal swings, or economic shifts.

When forecasting is done well, the benefits are clear and measurable: lower costs, greater agility, higher customer satisfaction, better supplier relationships, and stronger collaboration across teams.

Demand forecasting, for example, can result in a 3–4% increase in revenue due to reduced lead times and better product availability. To get these results, a BI tool is often necessary for insights and reporting.

Demand forecasting can transform supply chain management.

Types of Forecasting Methods

There are many ways to forecast in a supply chain. Some methods rely on numbers and models, others depend on expert insight. Each has its role.

The list below covers the most common and effective forecasting approaches used today. In many cases, businesses combine methods to get more accurate and reliable results.

Quantitative Methods

Quantitative forecasting uses historical data, statistical models, and mathematical formulas. These methods often require supply chain analytics tools or software; they work well when you have enough quality data to find patterns and trends.

Here are some widely used quantitative approaches:

- Time series analysis: Examines patterns in historical data over time. It helps forecast future demand based on past trends, seasonality, or cycles.

- Causal models: Identify cause and effect between variables. For example, how weather or marketing spend might influence sales.

- Predictive analytics: Uses algorithms and data models to forecast outcomes. Often powered by machine learning, it adapts to new data and learns over time.

- Exponential smoothing: Gives more weight to recent observations to quickly respond to changes in demand while still accounting for historical data.

- Life cycle modeling: Predicts demand based on where a product is in its life cycle: new, growing, mature, or declining. Especially useful for new product planning.

Qualitative Methods

Qualitative forecasting relies on expert opinions, market knowledge, and informed judgment. These methods are useful when there is little historical data or when the environment is highly uncertain.

While qualitative methods can be subjective, they offer valuable context and are often combined with quantitative models for better results.

Common qualitative methods include:

- Delphi method: A structured process that gathers insights from a panel of experts through several rounds of anonymous feedback and discussion.

- Market research: Uses surveys, interviews, and customer data to estimate future demand. Helpful for launching new products or entering new markets.

- Expert judgment: Leverages the experience and knowledge of internal stakeholders to make informed forecasts.

- Historical analysis: Looks at similar past events or patterns to project future outcomes. Often used for rare or disruptive events.

- Panel consensus: A group of experts discuss and agree on a forecast together. This approach is less structured than Delphi but still based on expert input.

Key Supply Chain Forecasting Techniques

Some of the most widely used forecasting techniques used in supply chain management include:

- Moving averages: Averages recent data points to smooth out short-term fluctuations. Useful for identifying overall trends.

- Regression analysis: Examines relationships between variables, such as how pricing or promotions affect demand.

- Machine learning models: Analyze large datasets and detect complex patterns. Can adapt quickly to changing conditions and improve over time.

Below is a detailed table that compares the techniques and methods discussed.

Quick Comparison of Forecasting Techniques and Methods in Supply Chain Management

| Method | Type | Best Use Case | Key Challenge |

|---|---|---|---|

| Moving Averages | Quantitative | Short-term trend smoothing | Lags behind sudden demand shifts |

| Regression Analysis | Quantitative | Linking demand to external factors | Requires strong data relationships |

| Machine Learning Models | Quantitative | Large, fast-changing environments | Requires significant data and tuning |

| Time Series Analysis | Quantitative | Stable historical data | Less responsive to sudden changes |

| Causal Models | Quantitative | Understanding external influences | Needs careful variable selection |

| Predictive Analytics | Quantitative | Data-rich, dynamic markets | Requires advanced tools and expertise |

| Exponential Smoothing | Quantitative | Detecting short-term trends | Can miss seasonal or long-term patterns |

| Life Cycle Modeling | Quantitative | Forecasting seasonal or new product demand | Needs accurate classification of product stage |

| Delphi Method | Qualitative | New markets or product launches | Time-consuming and subjective |

| Market Research | Qualitative | Understanding customer preferences | Can be costly and limited in scale |

| Expert Judgment | Qualitative | When data is unavailable or unclear | High risk of human bias |

| Historical Analysis | Qualitative | Reviewing past disruptions or irregularities | May not apply to current market conditions |

Forecasting Models and Tools: What Businesses Use Today

Modern supply chain analytics tools are becoming more advanced, flexible, and data-driven. Many businesses now rely on specialized supply chain forecasting software to streamline planning, reduce errors, and improve responsiveness.

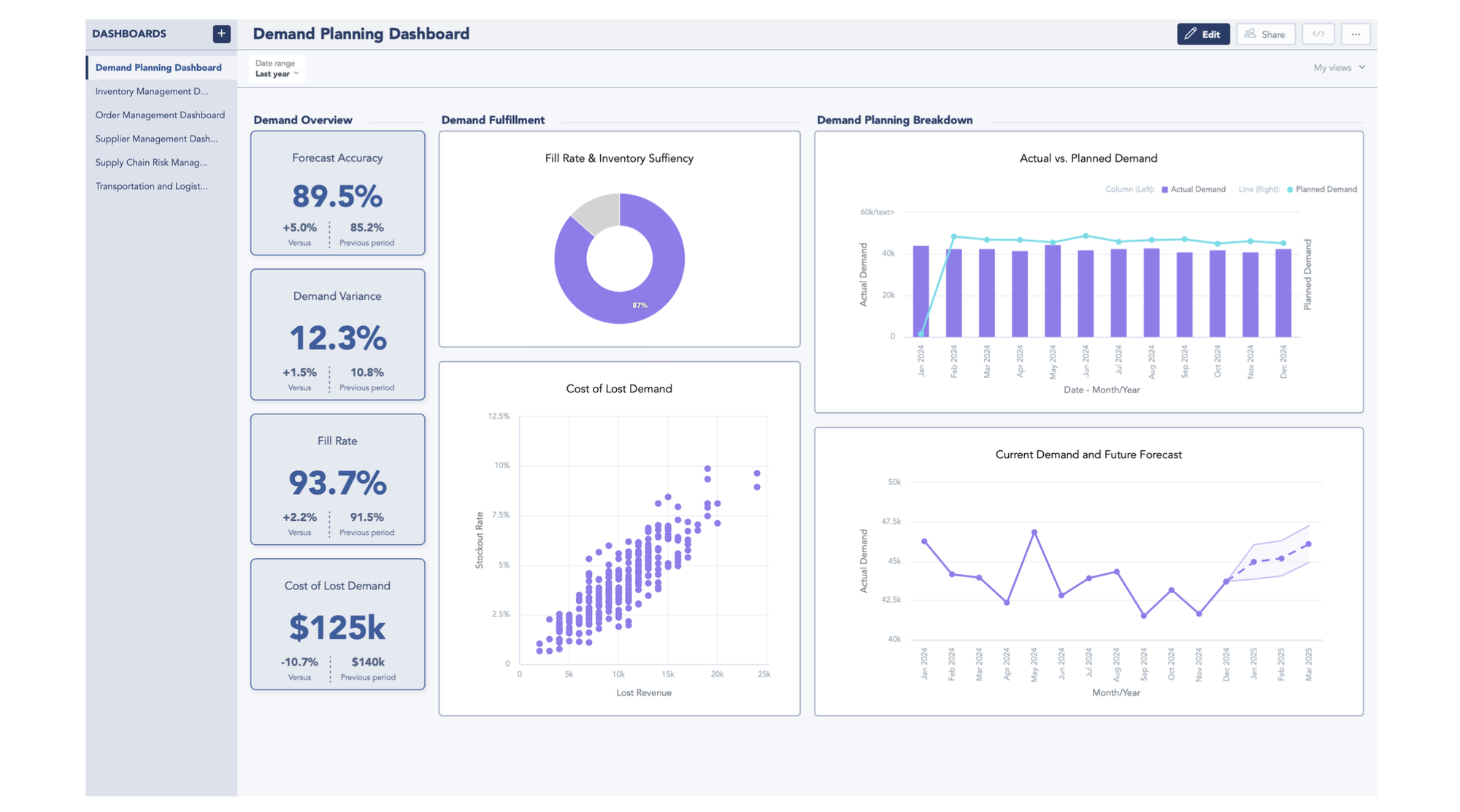

The output of these tools is often presented in user-friendly supply chain dashboards that allow stakeholders to quickly understand forecasts and potential impacts.

Modern BI tool features enable you to:

- Combine historical, real-time, and external data.

- Support both short- and long-term forecasting; a primary function of dedicated supply chain forecasting tools.

- Use built-in models like exponential smoothing, regression, and time series.

- Visualize data through customizable dashboards and reports.

- Alert users to anomalies, risks, or forecast deviations.

The right tools help teams adjust quickly to changes in demand, supply, or market dynamics. This is probably why 95% of organizations have increased their spending in supply chain analytics and plan to do the same next year.

Forecasting in a data analytics platform

Machine Learning and AI in Supply Chain Forecasting

AI and machine learning are reshaping how companies forecast demand and manage supply chains. These technologies analyze vast datasets quickly, identify patterns that humans may miss, and continuously improve over time.

Unlike traditional models that rely heavily on historical data, machine learning adapts to change. It can adjust to new trends, disruptions, or seasonality by learning from incoming data. This means forecasts become more accurate and responsive, even in complex or unstable environments.

One of the biggest advantages is real-time data analysis. Machine learning models process data from sensors, transactions, weather forecasts, and more in near real time. This enables demand sensing, where businesses detect and respond to changes as they happen, not days or weeks later.

The impact of machine learning is measurable. According to McKinsey, AI-driven supply chain forecasting can reduce forecasting errors by 20% to 50%. This translates into fewer stockouts, lower inventory costs, and faster response times.

5 Best Practices to Improve Supply Chain Forecasting

Having the right tools isn’t everything. To make accurate forecasts, you also need the right mindset and processes.

1. Forecast collaboratively: Involve teams across sales, marketing, operations, and finance. When everyone contributes their insights, the forecast reflects a fuller picture of demand and supply pressures.

2. Review and refine regularly: Forecasts should not be static. Set a regular schedule to review performance, adjust models, and update inputs. Markets change, and your forecasts should too.

3. Factor in external variables: Economic shifts, weather events, supplier risks, and market trends can all impact demand and supply. To stay ahead of unexpected changes, build models that consider more than just internal data.

4. Align forecasting with business goals: Make sure your forecasts support your wider strategy, whether it’s reducing costs, improving service levels, or expanding into new markets. This keeps forecasting relevant and actionable.

5. Make the forecasts easy to understand and act on: Forecasts should lead to decisions. Use clear visualizations, alerts, and summaries that help teams act quickly, not just analyze data.

Small improvements in processes can lead to big gains in accuracy, agility, and customer satisfaction.

Common Issues, Errors, and Bias in Supply Chain Forecasting

Even the most advanced forecasting systems are vulnerable to errors. Many of these issues come from how data is handled or how decisions are made around it.

Data issues are a major blocker. Missing values, inconsistent formats, or delays in data updates can lead to flawed outputs. Without a clean data pipeline, even the best model will fail.

Assumptions often go unchecked. Forecasts sometimes rely on outdated rules or oversimplified logic. If assumptions are not reviewed regularly, they can reduce accuracy and slow reaction time.

Bias is harder to spot but just as damaging:

- Model bias happens when the algorithm leans too heavily on certain variables or patterns that no longer apply.

- Human bias enters when teams override model outputs based on instinct, past habits, or internal pressure.

Fast-changing markets can expose these weaknesses quickly. When conditions shift, models and processes that worked before may no longer be effective. Without a system that flags unusual activity or adapts quickly, errors multiply.

The fix is not to eliminate all error. It is to spot risks early, test assumptions often, and build a process that adapts, not just predicts.

How Can You Stay Ahead When it Comes to Supply Chain Forecasting?

Businesses that succeed are the ones that evolve their forecasting processes, not just during a crisis but as part of everyday operations. This requires not only investing in the right tools but also having a strong grasp of different supply chain forecasting methods and knowing when to leverage each.

Getting ahead is about more than having data; it is about turning that data into fast, reliable insights that drive action. This means investing in tools that are flexible, scalable, and built for today’s pace of change.

Your analytics ought to be:

- Easy to integrate across teams and data sources.

- Powerful enough to handle advanced forecasting models.

- User-friendly so decision-makers can act quickly.

This is where GoodData comes in.

We help organizations build smarter models, connect real-time data, and deliver insights directly to business users.

Whether you want to reduce costs, react faster to market changes, or improve service levels, the platform gives you the tools to make it happen. Get a personalized demo to see how GoodData can transform your supply chain today.

FAQs

Common errors include relying on outdated data, ignoring external factors, and using the wrong forecasting model. Human bias and poor collaboration between teams can also lead to inaccurate forecasts that disrupt planning and inventory management.

It usually starts with collecting data, selecting a forecasting method, building a model, and then testing it. From there, businesses monitor results, adjust based on feedback, and improve accuracy over time using new data or updated assumptions.

Poor data quality, unexpected market changes, supply disruptions, and flawed assumptions affect accuracy. Forecasts also suffer when teams don’t collaborate or when external events like weather or economic shifts are ignored.

Bias can distort forecasts by overestimating or underestimating demand. This happens when models rely too much on past trends, or when human judgment overrides data. The result is often excess inventory or stockouts.

Good forecasting reduces costs, prevents stockouts, and improves customer satisfaction. It also helps teams plan better, respond faster to changes, and make smarter decisions about production, inventory, and logistics.